Box gutter leaks on commercial buildings often happen when the outlet becomes blocked.

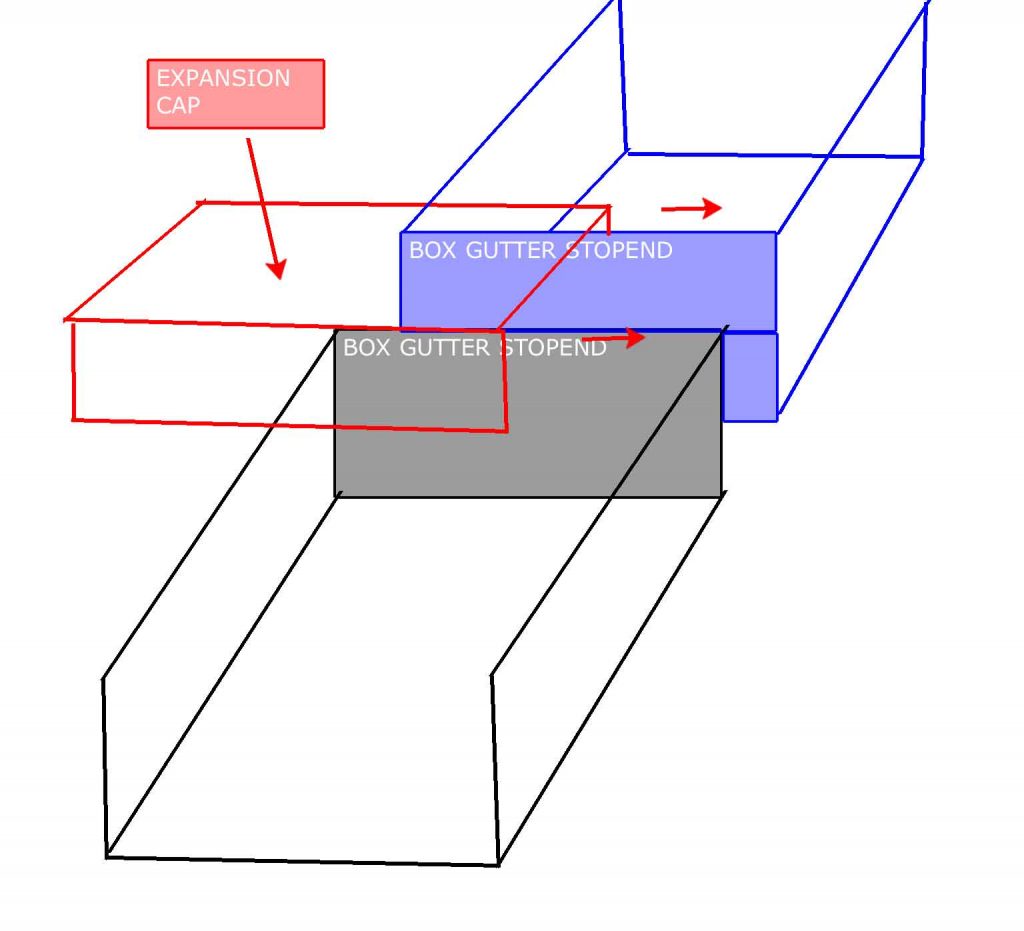

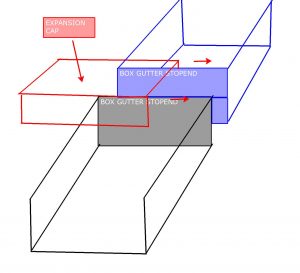

Longer box gutters are typically constructed with a join about the half way mark. More if the box gutter is excessively long. At each join, the box gutter has an expansion joint. Traditionally, this was constructed by turning up the ends of each of the metal joining pieces to form 90 degree angles. A bridging cap then sits over the top. The bridging cap’s purpose is to stop water from entering the gap left between the upturned ends. The purpose of the upturns in the metal is to allow for expansion and contraction. This type of box gutter set up also has an outlet at each end to facilitate drainage.

Longer box gutters are typically constructed with a join about the half way mark. More if the box gutter is excessively long. At each join, the box gutter has an expansion joint. Traditionally, this was constructed by turning up the ends of each of the metal joining pieces to form 90 degree angles. A bridging cap then sits over the top. The bridging cap’s purpose is to stop water from entering the gap left between the upturned ends. The purpose of the upturns in the metal is to allow for expansion and contraction. This type of box gutter set up also has an outlet at each end to facilitate drainage.

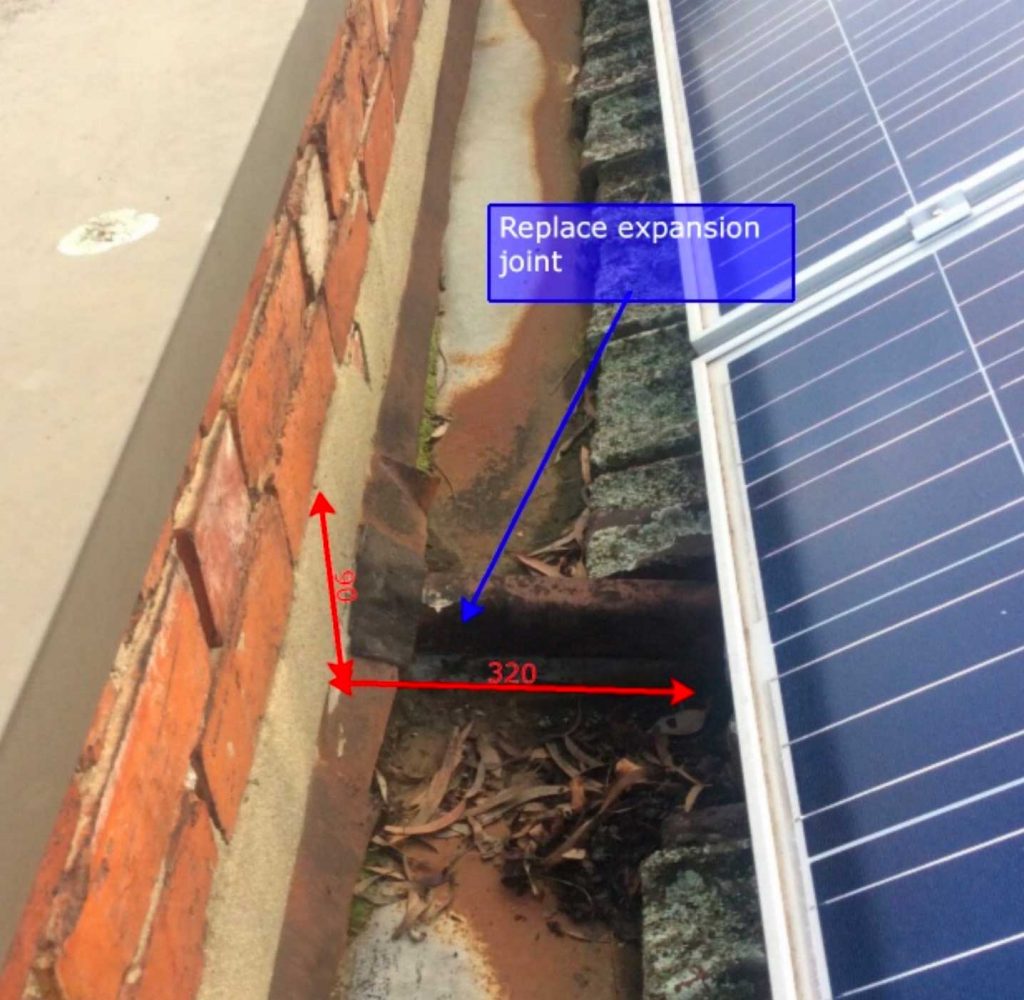

Though it meets current plumbing regulations, it is a cumbersome piece of engineering and it can create leaks when not properly installed.

Furthermore, if one of the downpipe outlets becomes blocked, the box gutter can quickly resemble a dam, filling the related section of box guttering until water finally overflows, usually back and inside the building.

A solution to this problem is to install a flat rubber expansion joint. This style of expansion joint allows the water to flow freely between both sections of the box gutter utilising the box gutter in its entirety.

A solution to this problem is to install a flat rubber expansion joint. This style of expansion joint allows the water to flow freely between both sections of the box gutter utilising the box gutter in its entirety.

Replacing the traditional expansion joint with a flat rubber expansion joint is a relatively cheap solution to overflowing box gutters. The solution is particularly cost effective where it would be difficult to install an overflow outlet, eg through a brick wall and out to the street below.

Call Roofrite today to arrange a quote for this cost effective solution to box gutter leaks on commercial buildings.